When it comes to vintage cars like the 1996 Pontiac G6 Hardtop, maintaining functionality and originality can be a rewarding challenge. One such component that often needs attention is the trunk hinge. Over time, these parts can wear out or break, leaving owners searching for cost-effective, accurate replacements. In this blog, we’ll dive into the process of reproducing a trunk hinge, answering frequently asked questions and offering expert insights to help you restore your vehicle with precision.

Why Reproduce a Trunk Hinge for a 1996 Pontiac G6?

The 1996 Pontiac G6 Hardtop is a beloved model known for its sleek design and hardtop functionality. However, original trunk hinges for this vehicle are often difficult to find due to limited production and the passage of time. Reproducing a trunk hinge ensures:

- Restored functionality: A properly functioning hinge allows smooth opening and closing of the trunk.

- Maintained originality: Custom reproduction preserves the vehicle’s aesthetic and structural integrity.

- Cost-effectiveness: Creating a custom hinge can be more affordable than sourcing rare OEM parts.

Frequently Asked Questions

1. What materials are best for reproducing a trunk hinge?

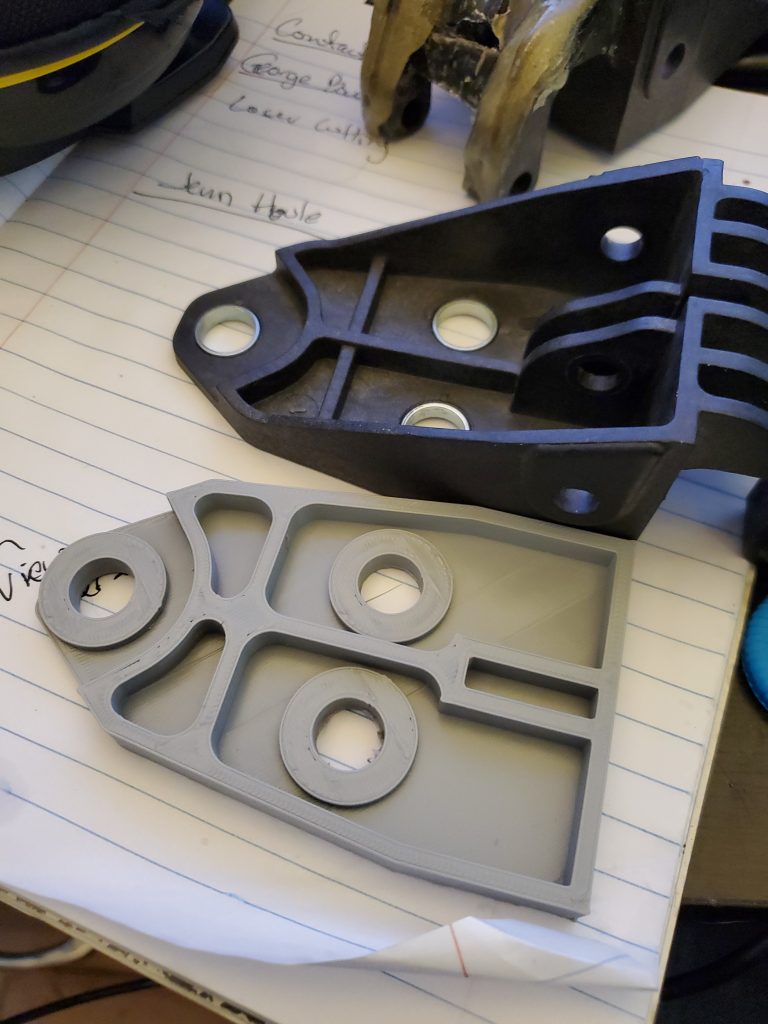

High-strength materials such as steel or aluminum are ideal for durability and longevity. Advanced techniques like 3D printing can also produce hinges using industrial-grade thermoplastics or metal-infused materials.

2. How can I ensure the reproduced hinge fits perfectly?

Precision is key. Start by measuring the original hinge or the space it occupies. Use CAD software to create an exact replica. Partnering with a professional service, like Creatorpult in Massachusetts, ensures accurate dimensions and seamless installation.

3. What tools are needed for the reproduction process?

To reproduce a hinge, you may need:

- CAD software for design.

- 3D printer or CNC machine for fabrication.

- Finishing tools for smoothing edges and ensuring proper alignment.

4. Is it possible to improve the hinge design during reproduction?

Absolutely! This is an excellent opportunity to enhance the hinge’s strength, add rust-resistant coatings, or even modify it for smoother operation without compromising the original design.

Steps to Reproduce a Trunk Hinge

- Assess the Damage: Begin by examining the broken or worn-out hinge. Identify any weak points or signs of wear that can inform the new design.

- Take Accurate Measurements: Use calipers to measure the original hinge’s dimensions, including pivot points, angles, and attachment areas.

- Create a Digital Model: Use CAD software to design a replica or improved version of the hinge. This digital file will guide the fabrication process.

- Fabricate the Hinge: Utilize a 3D printer or CNC machine to create the hinge. For vintage car enthusiasts, Creatorpult provides custom 3D printing Solution to ensure top-notch results.

- Test and Install: After fabrication, test the hinge for fit and function. Make any necessary adjustments before installation.

Why Choose Creatorpult for Custom Reproduction?

Recently, a client approached Creatorpult with a broken extension bar for a GoPro mount. Using advanced 3D printing technology, we reproduced precise dimensions and selected strong materials like polycarbonate to ensure durability and functional accuracy. The client was thrilled with the results, reinforcing our reputation for quality craftsmanship and customer satisfaction. Located in Massachusetts, Creatorpult specializes in custom solutions for car enthusiasts and beyond.

Bringing Your Pontiac G6 Back to Life: The Power of Precision and Expertise

Reproducing a trunk hinge for a 1996 Pontiac G6 Hardtop doesn’t have to be a daunting task. With the right materials, tools, and expertise, you can restore your vehicle’s functionality while preserving its classic charm. If you’re looking for a reliable partner in custom fabrication, Creatorpult is here to help.